Model based Enterprise (MBE) Implementation Services

Fully exploit your MBD Investments For a measurable ROI

MBD is to MBE like PDM is to PLM. It is the core process and application infrastructure required to enable the Model-based Enterprise. Organizations driving to a Model-based Enterprise which provides a measurable ROI must establish a robust MBD Environment that could include but may not be limited to:

- Model-based Standards for GD&T

- PMI Standards to enable a high first pass yield of the downstream Supply Chain processes which will consume the Model-based Definition

- Automated Model, Revision, and Derivative Data Quality Checking

- One to “n” Model-based Definitions which enable the creation of Technical Data Packages (TDP) across the entire Part Family Tree

- Technical Data Publishing process and application environment

- Extensions to the Engineering Release process to enable execution of specific data duality checks at specific lifecycle states by Part Family

- Extensions to the Engineering Release process to enable creation of specific derivative files and the publication of the Technical Data Packages at specific lifecycle states

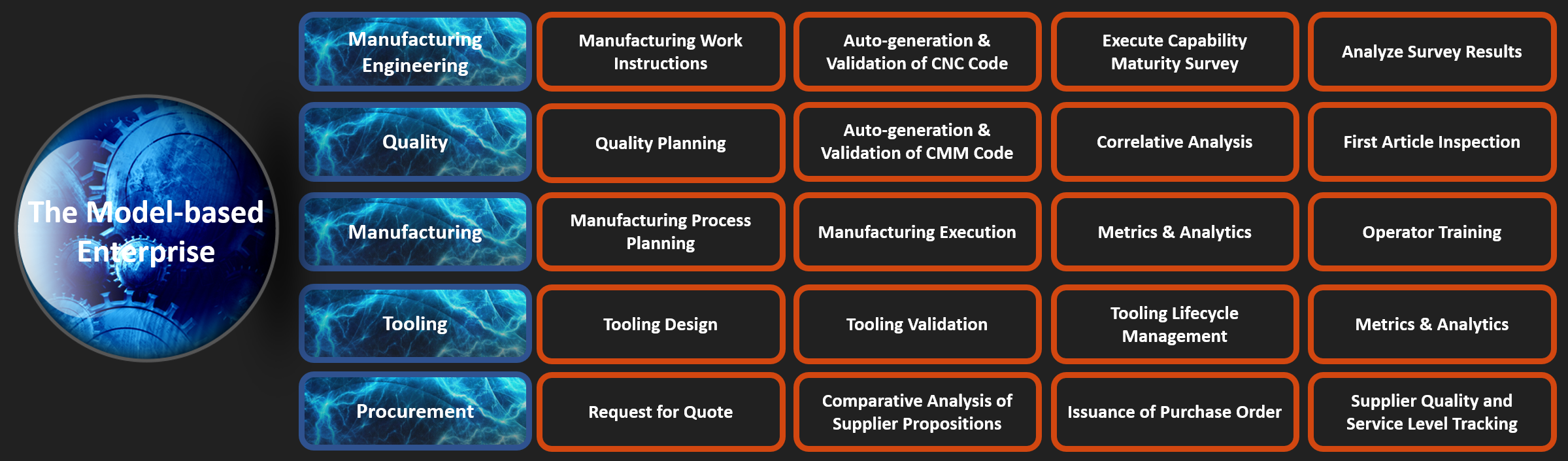

MBE Implementation Services

- Integration of MBD to Manufacturing Work Instruction creation, release, and dissemination processes

- Integration of MBD to Tooling design, release, and lifecycle management processes & systems processes

- Setup & integration of MBD to Metrology to enable automated generation and faster validation of CMM Code

- Integration of Metrology Data back in to MBD to better enable predictive analysis and operational troubleshooting

- Integration of MBD to manufacturing process planning, execution and analysis processes/systems

- Integration of MBD to Quality Planning and First Article Inspection processes/systems

- Integration of Quality Data back in to MBD to better enable quality analytics and troubleshooting

- Integration of MBD through the Procurement vendor RFQ, vendor analysis & vendor acquisition processes

- Establish Outsource Supplier Maturity and set policies, procedures, and management/measurement techniques to encourage/drive an increase in supplier maturity that will enable their exploitation of your MBD Investments and provide a return on investment

- Incorporation of supplier metrics

Where’s Money – Partial Listing

DSA has a comprehensive evidentiary library of real ROI Calculations from multiple customer initiatives and can assist you to position MBE for the appropriate level of funding and support you will require from your Executive Sponsors

Early Adopters Report:

- 25% to 40% reduction in Manufacturing Work Instruction creation, release, and dissemination time

- 30% reduction in Producibility Reviews

- 60% reduction in Producibility Non-conformance Remediation

- 10% to 35% reduction in scrap

- 15% to 20% reduction in supplier rework

- 60% reduction in CMM programming & validation

- 30% to 50% reduction in Tooling design, validation and release cycle

- 20% to 35% reduction in tool changeover costs

- 60% to 95% reduction in defects in the FAI results

- 45% to 90% reduction in time to assemble/disseminate RFQ and evaluate vendor responses